DragonLAIR Pro

DragonLAIR Pro is remote hosting automation built for facilities that can't afford failures. Field-proven at HCRO with 2000+ cycles. Custom-designed for your building.

This product requires a custom quote based on your specific requirements and configuration.

We'll get back to you within 24 hours with a custom quote

When Standard Automation Can't Handle the Job

The DragonLAIR Pro is a custom-engineered chain drive system for observatory buildings that exceed the capabilities of standard roll-off roof automation. Buildings up to 20 feet wide, 60 feet long, and weighing thousands of pounds-the kind that house multiple research-grade telescopes or serve as remote hosting facilities for paying customers. When your building is too large for off-the-shelf solutions and too critical for DIY experiments, the Pro is what we build.

See it in action

Why Chain Drive? Why Custom?

We've seen what happens when people try to automate large buildings with equipment that wasn't designed for the job. Gate openers running beyond their rated load. Rack-and-pinion systems that worked fine until the building settled and the gears stopped meshing. DIY solutions that move the roof most of the time-but "most of the time" isn't acceptable when you're hosting $100,000 of someone else's equipment under Bortle 1 skies.

Chain drive solves problems that rack-and-pinion can't:

Building Settling: Over months and years, buildings shift. With rack-and-pinion, that means re-meshing gears or watching them grind. Chain drive is inherently forgiving. Tension adjusts naturally. The system keeps working while the building does what buildings do.

Long Runs: A 60-foot rack is expensive, difficult to align, and creates multiple potential failure points at every joint. A 60-foot chain runs between anchor points on your building, easily routing up and over solid impediments while costing a fraction of the equivalent rack.

Proper Load Distribution: On the largest buildings, a direct-drive motor bearing can't support both the torque required to move the structure and the weight of a long, heavy chain. Our intermediate shaft with pillow block bearings carries the chain weight-the motor just provides power. We learned this lesson early (a burned-out bearing taught us well), and now it's standard on long-chain installations.

Every DragonLAIR Pro is custom-engineered for your specific building. There's no "medium" or "large" size-we design the gear reduction, chain routing, and motor selection based on your building's weight, dimensions, and operating requirements.

Key Benefits

Custom Engineering for Buildings That Don't Fit the Mold

Your building isn't standard, so your automation shouldn't be either. During consultation, we evaluate your structure's weight, dimensions, construction type, and operating requirements. We determine the optimal gear ratios, motor size, chain routing, and mounting locations. You get a system designed specifically for your building-not a generic kit with fingers crossed.

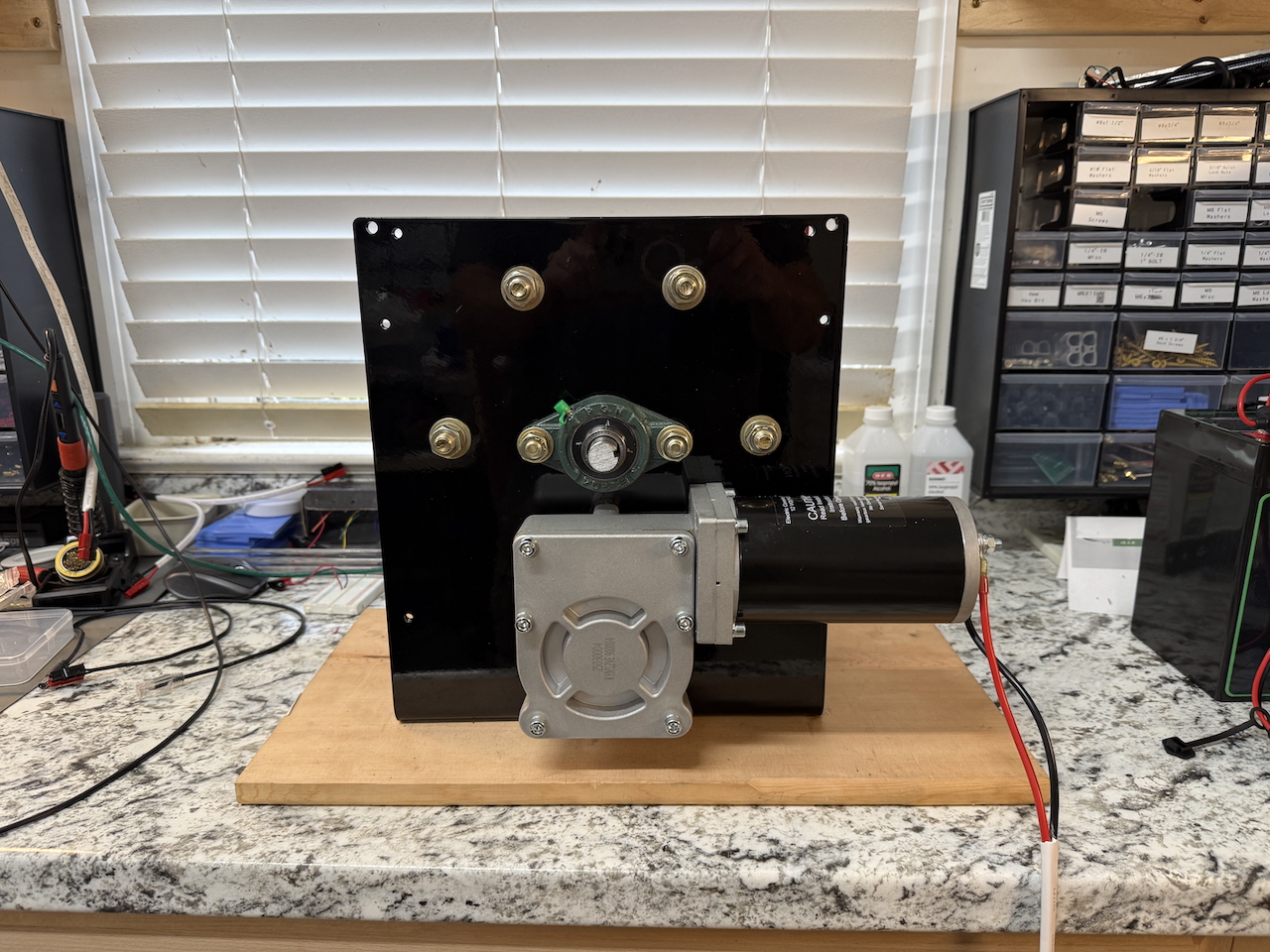

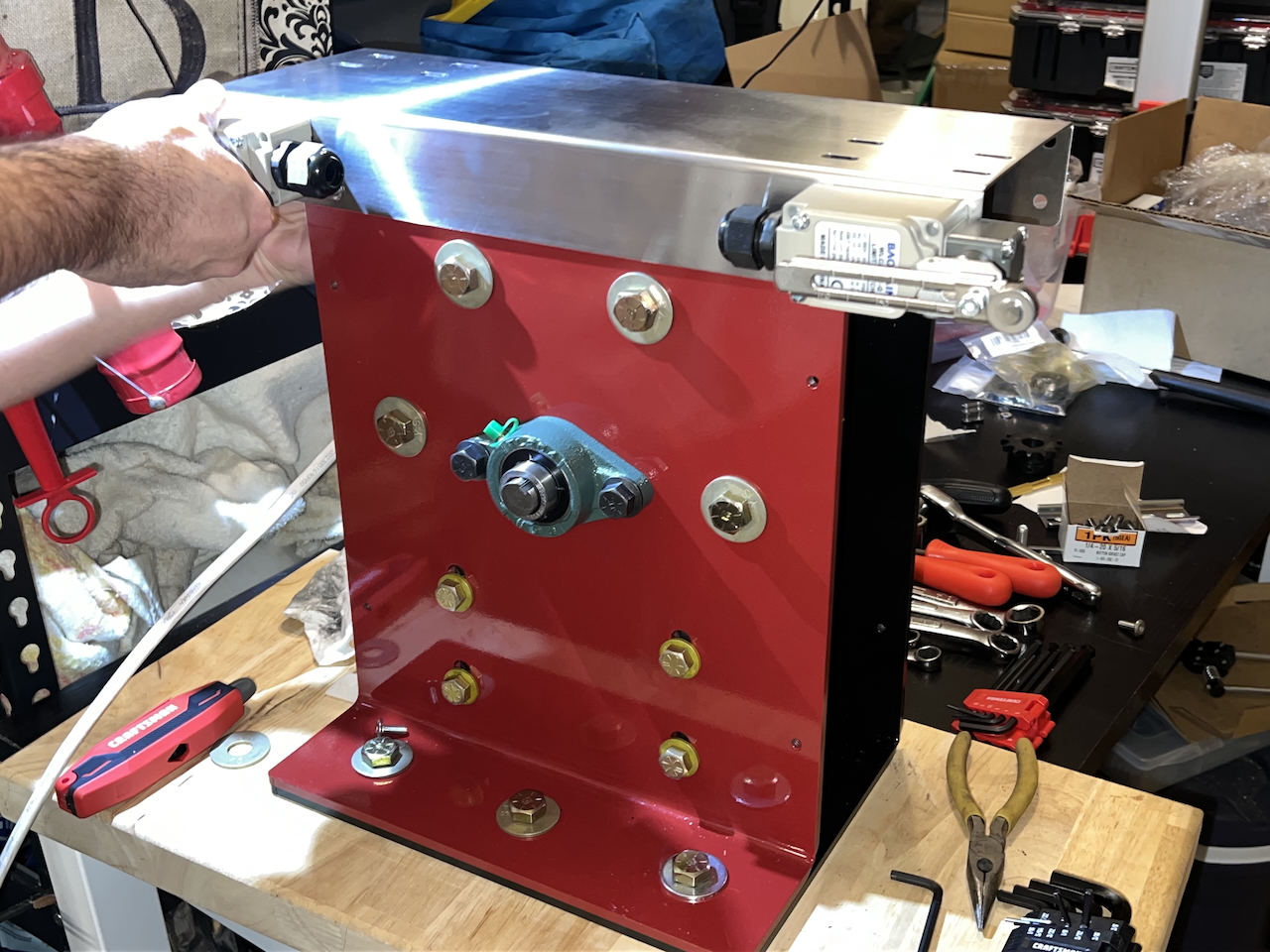

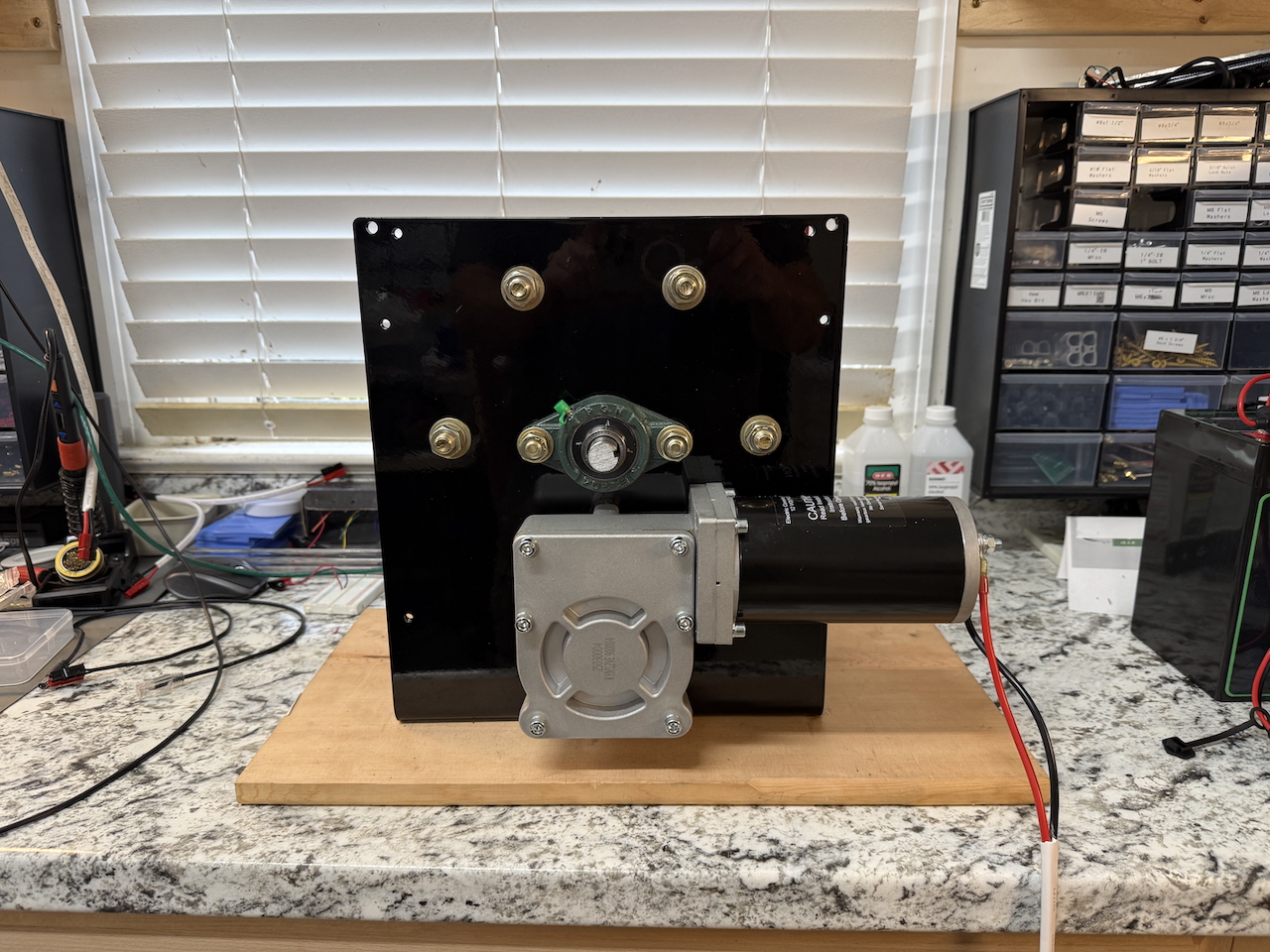

Intermediate Shaft Design for Long Chain Runs

For buildings requiring chain runs approaching 60 feet, the DragonLAIR Pro uses an intermediate shaft supported by pillow block bearings. This shaft carries the weight of the long, heavy chain-potentially 25+ pounds-while the motor handles only the primary drive chain. The result: proper load distribution, reduced bearing stress, and dramatically extended system life. This isn't theoretical engineering; it's what we added after field experience showed us what happens when you skip it.

Customizable Gear Reduction

Not every building needs the same torque-to-speed ratio. Some require maximum torque to overcome friction and inertia. Others benefit from faster movement. The Pro system offers three adjustment points: primary gear, driven sprocket, and drive sprocket. During engineering, we determine the ideal configuration for your building's characteristics. Need to tune it later? The flexibility is built in.

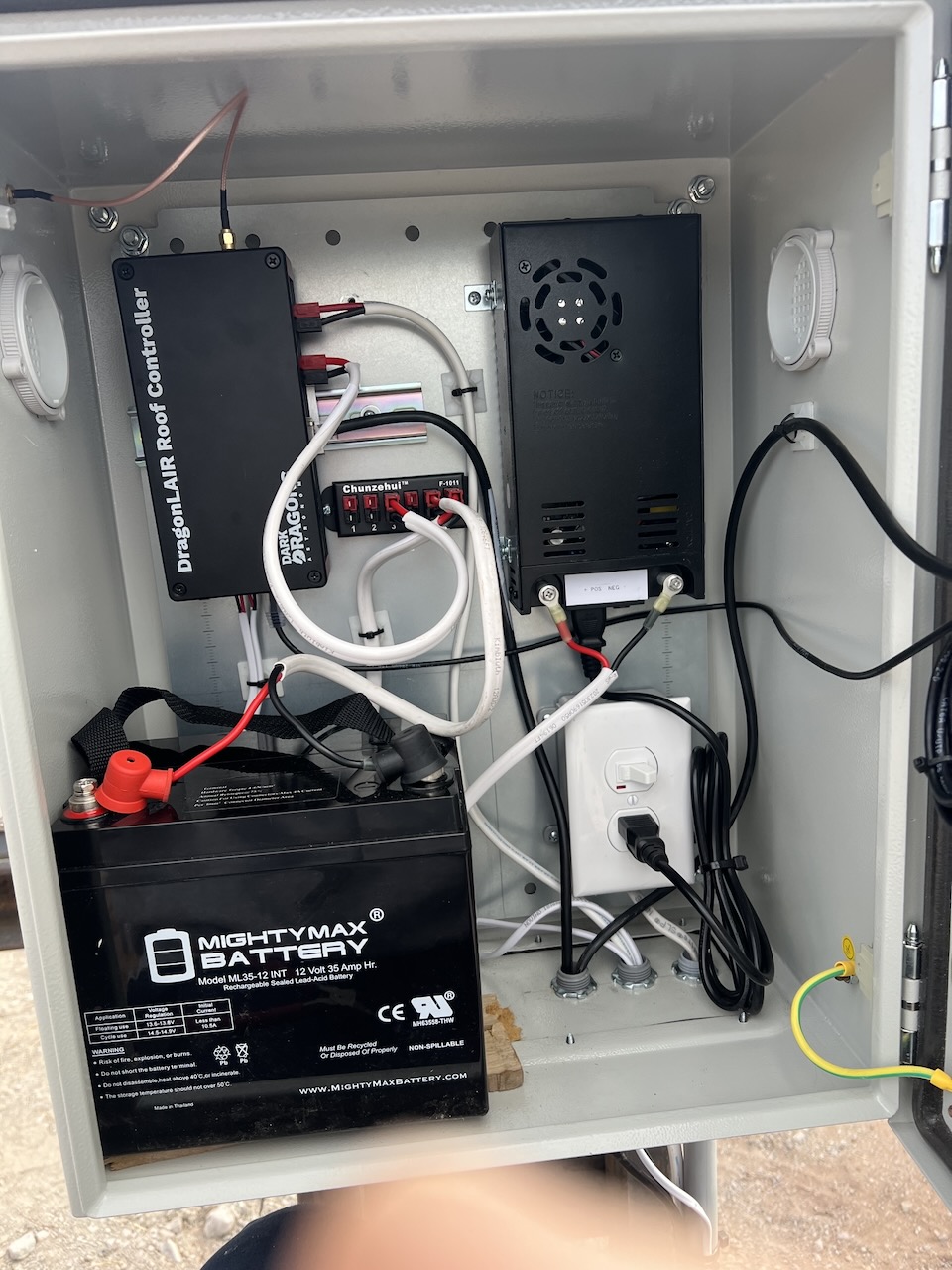

Built-In Automation for Remote Hosting

Most Pro installations serve remote hosting facilities-operations where multiple customers share telescope time under the same roof. These facilities don't run imaging software that commands the roof; they need the roof to manage itself. The DragonLAIR controller's built-in automation handles this: automatic open at sunset based on sun altitude, automatic close at dawn, weather-triggered closure when conditions turn unsafe. Every customer's telescope gets access to clear skies without anyone writing a custom script.

Motor Options for Any Load

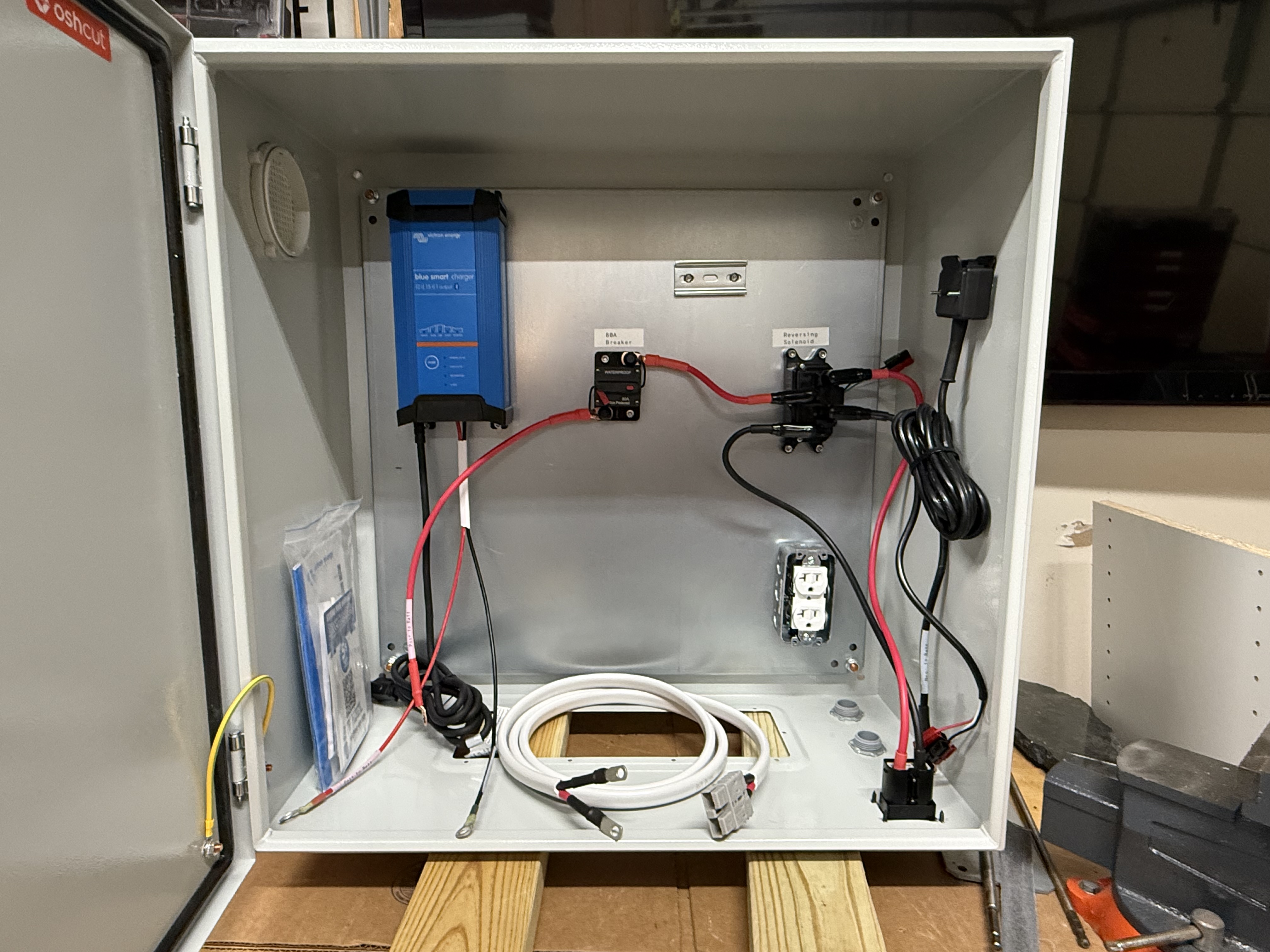

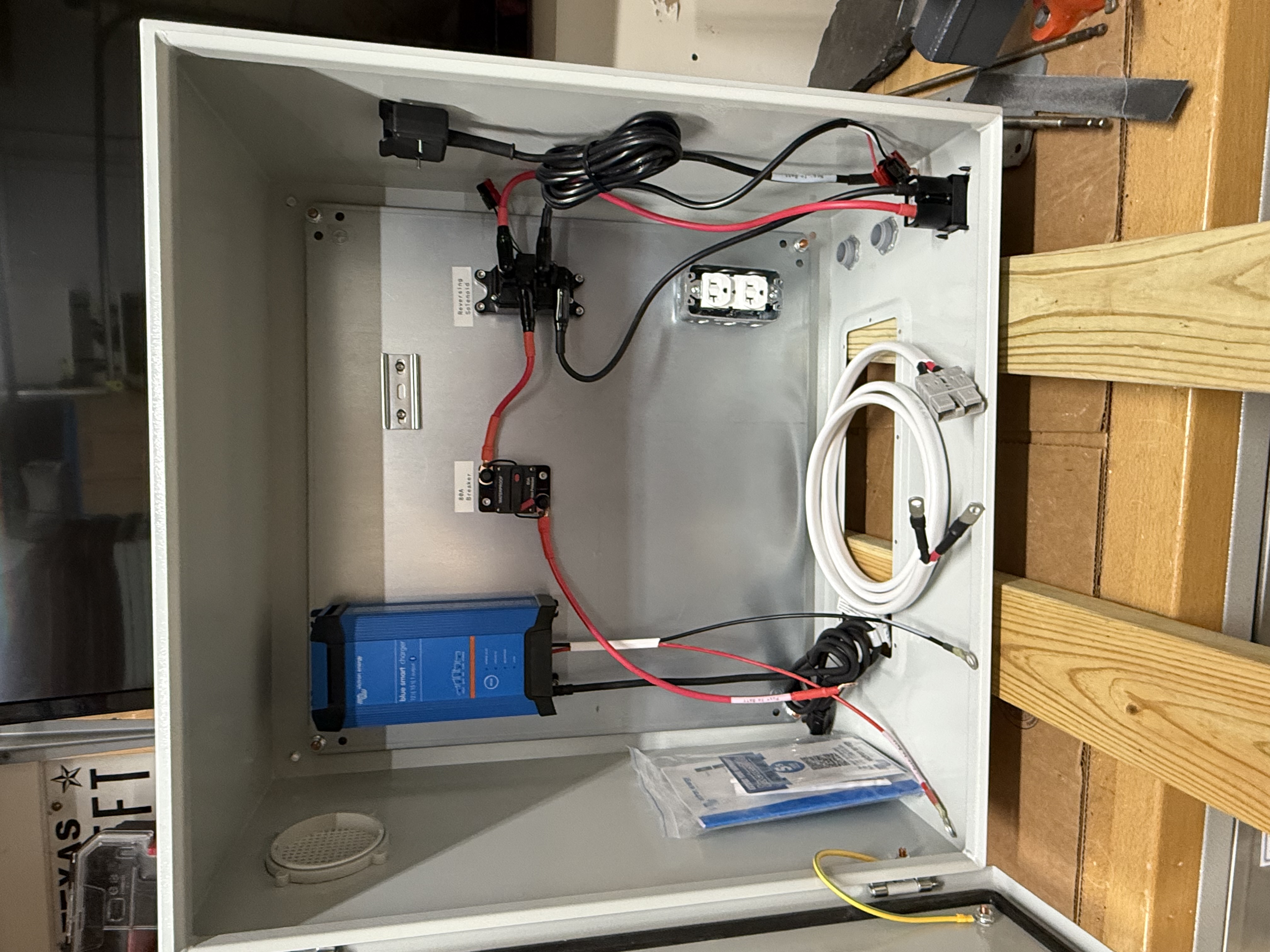

The Pro system supports 600W, 900W, and 1200W motors. For smaller Pro installations, the 600W motor with direct DragonLAIR control handles the job. For the largest buildings, we pair 900W or 1200W motors with external high-current solenoids. The DragonLAIR provides the logic and safety functions; the solenoid handles the amperage. We compensate for the loss of slow start/stop with shock-absorbing springs at the chain attachment points-smooth operation without stressing the controller's electronics.

Quieter Operation Than Rack-and-Pinion

Chain drive is inherently smoother and quieter than gear mesh. For residential-adjacent installations or shared facilities where noise matters, this isn't a minor detail. Your neighbors won't hear your observatory open at 2 AM.

What's Included

Every DragonLAIR Pro is custom-quoted based on your requirements. A typical system includes:

Drive System:

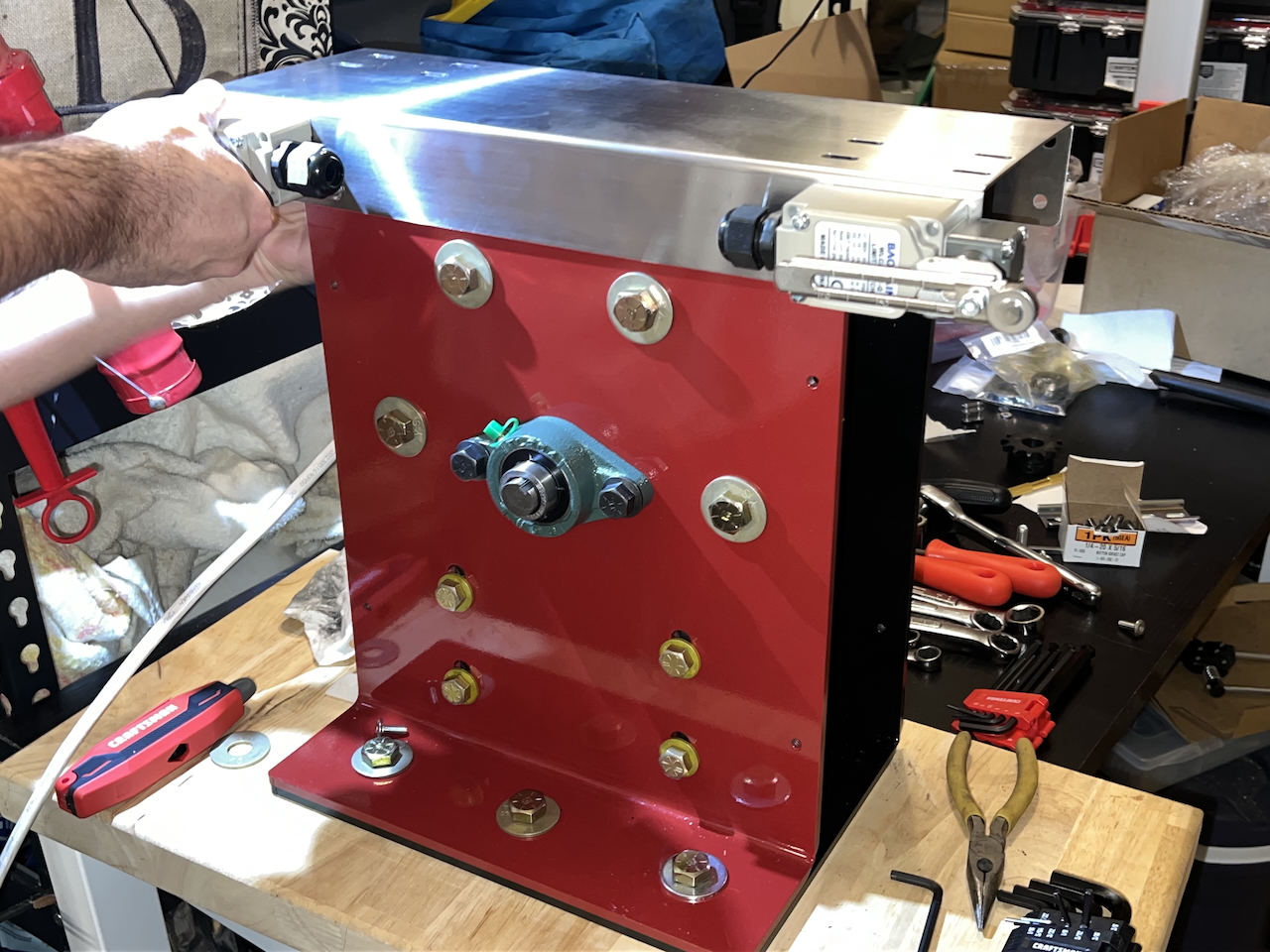

- Custom weld-on mounting plate designed for your building structure

- Drive unit assembly (motor, sprockets, gear system)

- Intermediate shaft with pillow block bearings (for long-chain installations)

- All sprockets (drive, driven, idlers as required)

- Chain (custom length, typically #40 or as required)

- Protective covers (side and top)

- Shock-absorbing springs for chain attachment

Hardware:

- Grade 8 zinc chromate structural bolts

- Stainless steel cover fasteners

- All spacers and mounting hardware

Engineering:

- Pre-installation consultation

- Custom system design for your building

- Mounting template for proper placement

- Engineering documentation

Optional:

- DDA installation services (strongly recommended)

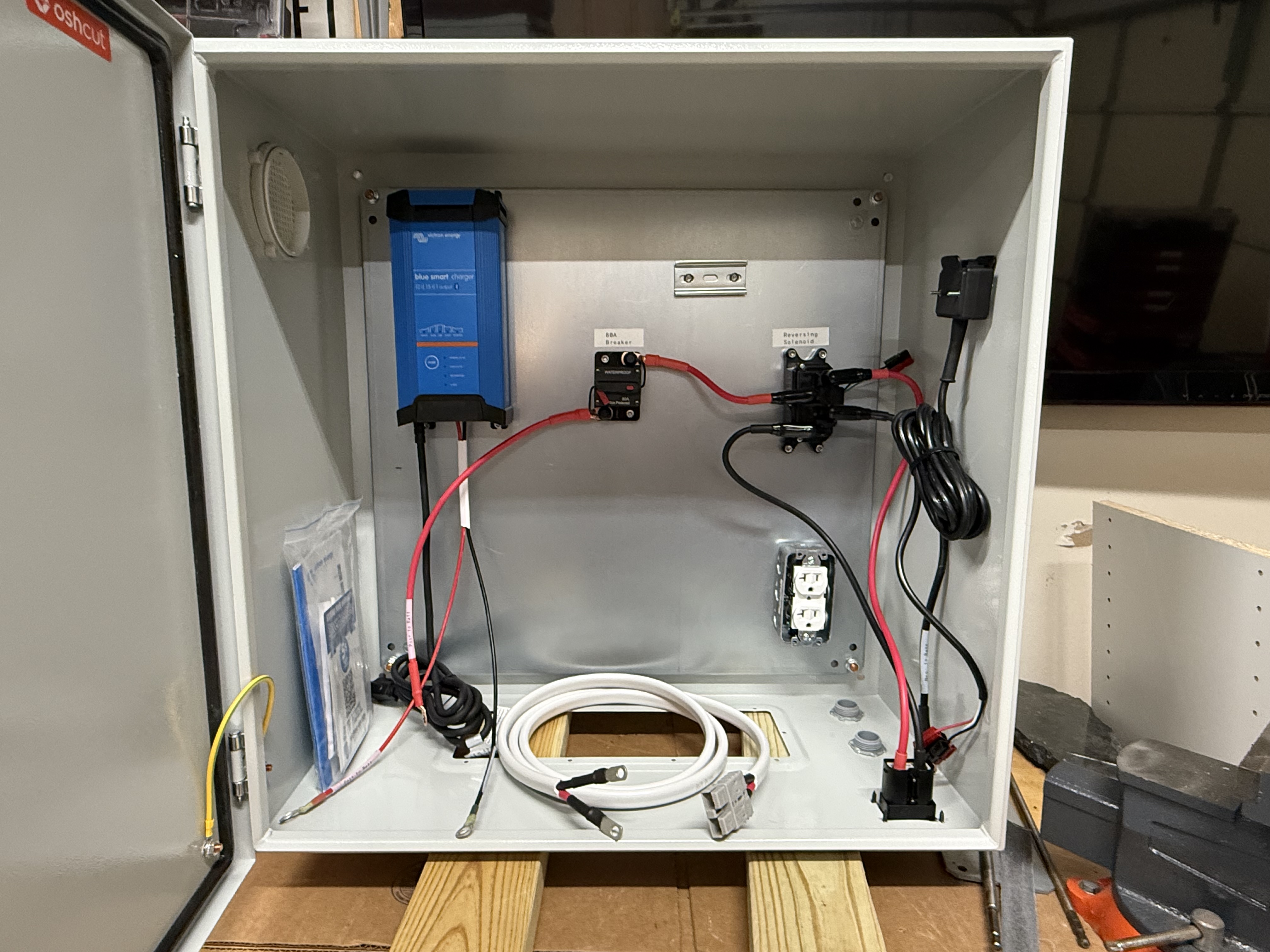

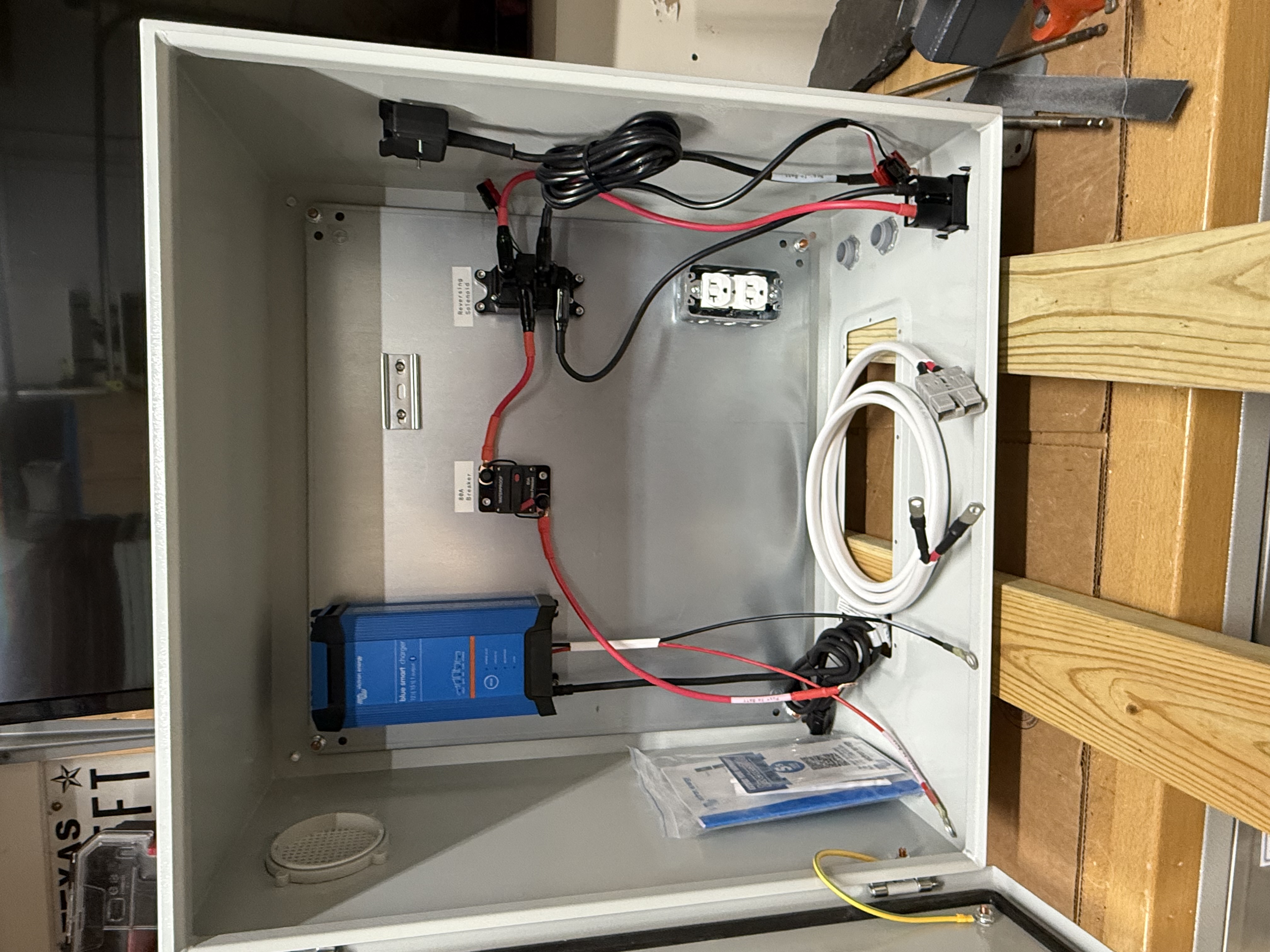

- DragonLAIR WiFi Controller (if not already owned)

- External high-current reversing solenoid (for 900W/1200W motors)

- Additional safety sensors

Technical Specifications

| Specification | Value |

|---|---|

| Maximum Building Size | 20 ft wide × 60 ft long |

| Building Weight Capacity | 6,000+ lbs |

| Drive Type | Pull/pull chain system |

| Chain | #40 (or as required by application) |

| Chain Run Length | Up to 60+ feet |

| Motor Options | 600W, 900W, 1200W |

| Gear Reduction | Customizable (12-18 tooth at three points) |

| Cycle Time | ~1:45 for 50-foot building |

| Intermediate Shaft | Pillow block bearings (long-chain installations) |

| Power Requirements | AC on site or off-grid 12V system |

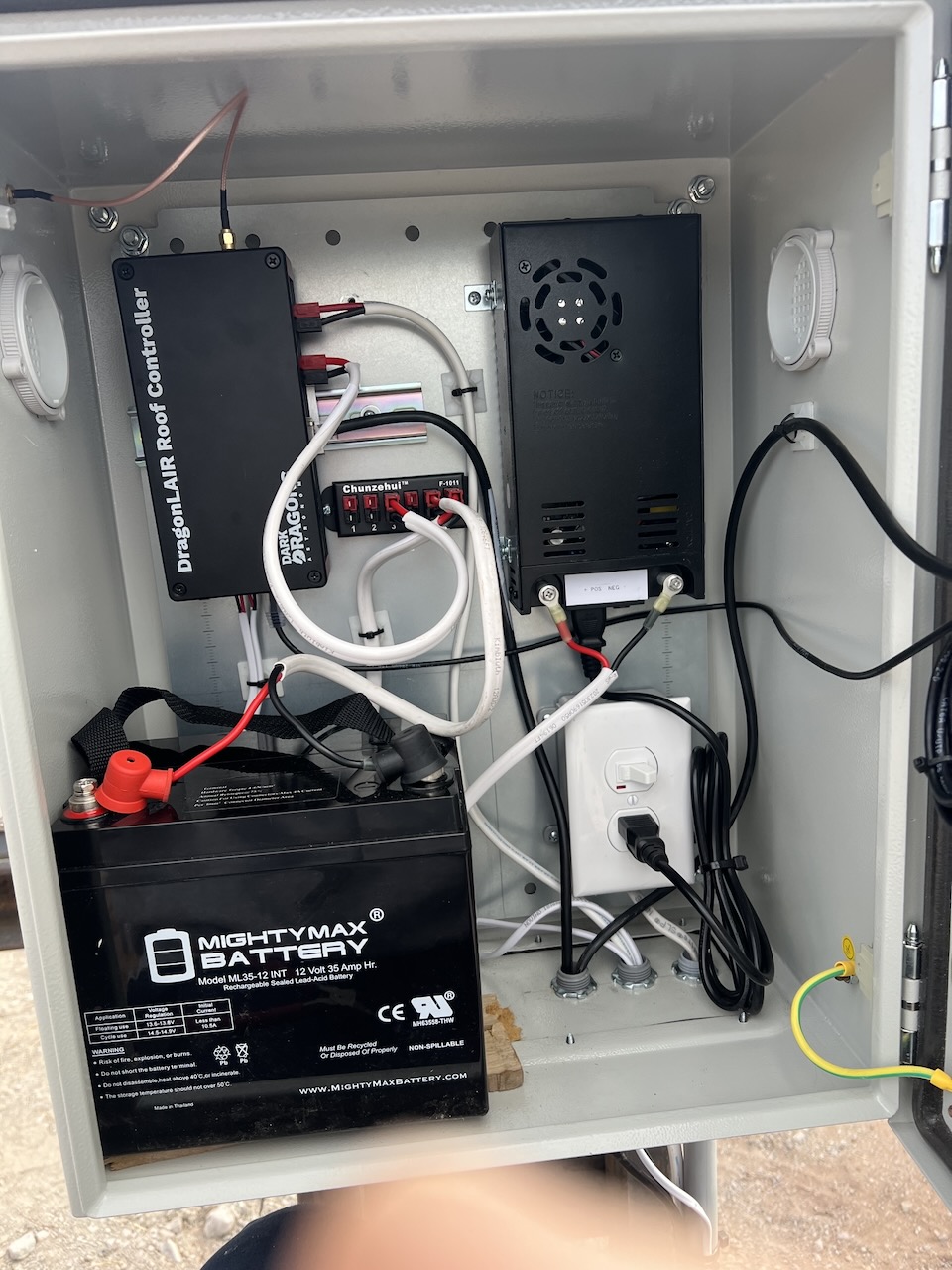

| Controller | DragonLAIR WiFi Controller (sold separately) |

| Software Support | ASCOM Alpaca, INDI, built-in web automation |

Integration/Compatibility

DragonLAIR Controller Integration:

The Pro system is designed to work with the DragonLAIR WiFi Controller (sold separately). You get:

- Web-based control from anywhere

- ASCOM Alpaca support for imaging software integration

- INDI driver for Linux/Mac systems

- Built-in automation (sun altitude triggers, weather safety)

- Four safety sensor ports

- Dual limit switches for travel endpoints

- Ethernet + WiFi with automatic failover

For Remote Hosting Facilities:

Most Pro customers rely on the controller's built-in automation-not imaging software commands. Configure sun altitude thresholds and weather triggers, and the roof manages itself. This allows all hosted telescopes to access clear skies automatically without facility operator intervention.

Software Compatibility:

When direct control is needed, the system works with:

- N.I.N.A.

- Sequence Generator Pro

- Voyager

- TheSkyX

- KStars/Ekos

- Any ASCOM Alpaca or INDI-compatible software

Installation/Setup Reality Check

DDA Installation (Strongly Recommended):

For Pro systems, we strongly recommend DDA installation services. The typical timeline:

- 1 travel day to your site

- 2 days for installation and commissioning

- 1 travel day return

Before we arrive, you'll place the mounting plate using the template we provide. This shows exactly where the chain will run when the system is mounted, ensuring proper placement before welding. This preparation significantly speeds the on-site installation.

Self-Installation:

If you choose to install yourself, you should be comfortable with:

- Chain alignment and tensioning

- Metalworking (welding, cutting)

- Precision mechanical assembly

- Electrical connections for motor and controller

We can provide detailed guidance as part of your quote, and we offer remote support during installation. However, given the scale and complexity of Pro systems, and the value of the equipment they protect-we strongly recommend letting us handle the installation.

Tools Required (Self-Install):

- Welding equipment

- Metal cutting tools

- Chain tensioning tools

- Standard hand tools and wrenches

- Multimeter for electrical verification

What You Need to Provide

Building Requirements:

- Building dimensions and weight estimate

- Building construction type (steel frame, Quonset, custom)

- Structural stiffness sufficient to prevent frame twisting under chain load

- Mounting points on building structure (with DDA guidance on placement)

Site Requirements:

- AC power on site OR functional off-grid 12V system

- Site access for installation (if DDA is installing)

- Internet connectivity (recommended for remote monitoring, not required)

Note: We have a recommended builder for Quonset-style observatories in the American Southwest. If you're starting from scratch, contact us for a referral.

Real-World Performance

The DragonLAIR Pro isn't a theoretical product. Eight systems are deployed and running right now-five at Howling Coyote Remote Observatory (HCRO) in New Mexico, plus three other installations across the desert Southwest.

Howling Coyote Remote Observatory:

HCRO operates under Bortle 1 skies, hosting multiple large research-grade telescopes for paying customers. Their buildings are massive steel structures-exactly the kind of installation where failure isn't an option. Our first Pro system went in more than two years ago. It's been running every clear night since.

Across all five HCRO installations, we've logged more than 2,000 combined open/close cycles. The intermediate shaft design, proper motor sizing, and chain drive reliability-these aren't marketing claims. They're proven in the field, night after night, in conditions ranging from cold desert winters to warm summers.

Lessons We've Already Learned:

We initially didn't include the extra pillow block bearing on long chain runs. A burned-out bearing taught us why it matters. Now it's standard.

We tried running a very large building on the 600W motor. It struggled. The 900W and 1200W motors exist because we learned where the limits are.

Controller uptime? Measured in months between restarts-and those restarts were for firmware upgrades, not failures.

You get a system that's already been refined through real-world experience. We've made the mistakes so you don't have to.

The Custom Engineering Process

1. Initial Contact

Tell us about your building:

- Dimensions (width, length, height)

- Weight estimate

- Construction type

- Current status (existing, under construction, planned)

- Operating requirements

2. Consultation

We discuss your specific installation:

- Building characteristics and challenges

- Optimal gear ratios for your weight and friction

- Motor selection

- Chain routing and attachment points

- Mounting plate placement

- Power system design

3. Custom Quote

You receive a detailed quote covering:

- Complete drive system components

- Engineering and documentation

- Installation services (if selected)

- Controller and accessories (if needed)

- Timeline and delivery

4. Engineering and Fabrication

Once approved, we design and build your system:

- Custom mounting plate with all necessary holes

- Gear reduction configured for your building

- Chain cut to length

- All components matched and tested

- 4-8 week lead time typical

5. Installation

DDA installation or supported self-install:

- Mounting plate placed using template (before DDA arrival)

- Drive system mounted and aligned

- Chain installed and tensioned

- Controller configured

- System tested and commissioned

6. Operation

Your Pro system protects your investment:

- Automatic operation based on conditions

- Remote monitoring and control

- Ongoing support from DDA

Protect What You've Built

A large observatory represents a massive investment-the building, the telescopes, the cameras, the mounts. For remote hosting facilities, it also represents your customers' trust and their equipment.

The DragonLAIR Pro is the automation system built for buildings this size and stakes this high. Custom-engineered for your specific structure. Chain drive that tolerates building settling. Intermediate shaft design that handles long runs properly. Field-proven at one of the world's premier remote hosting facilities.

Gate openers fail. DIY solutions work until they don't. Generic kits force your building to fit their limitations.

Your building is unique. Your automation should be too.

Contact us to discuss your installation and receive a custom quote. We'll evaluate your building, design the right system, and deliver automation that matches your investment.

Need help? Join our Discord community for installation guides, troubleshooting, and direct support.