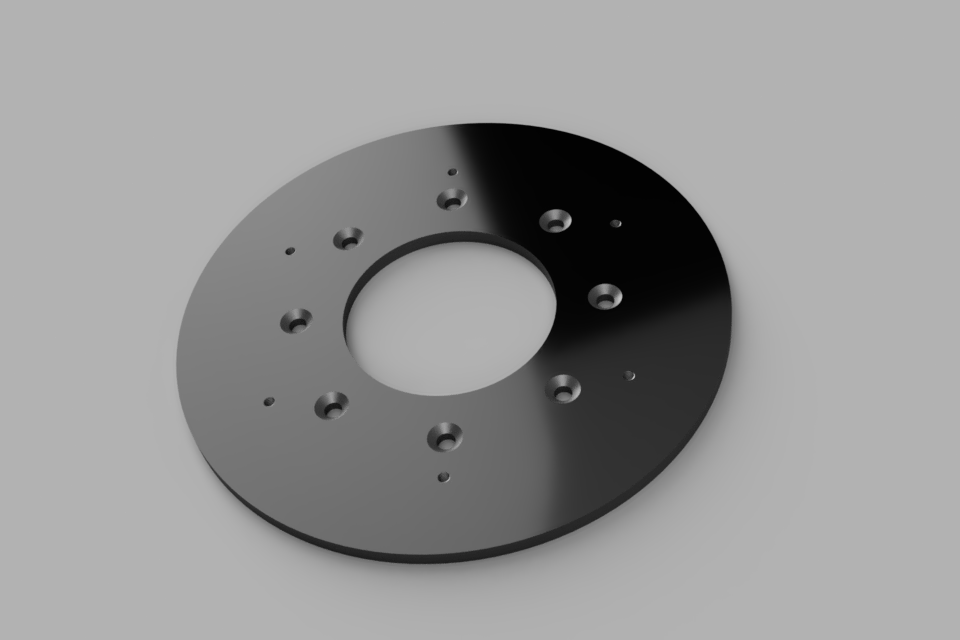

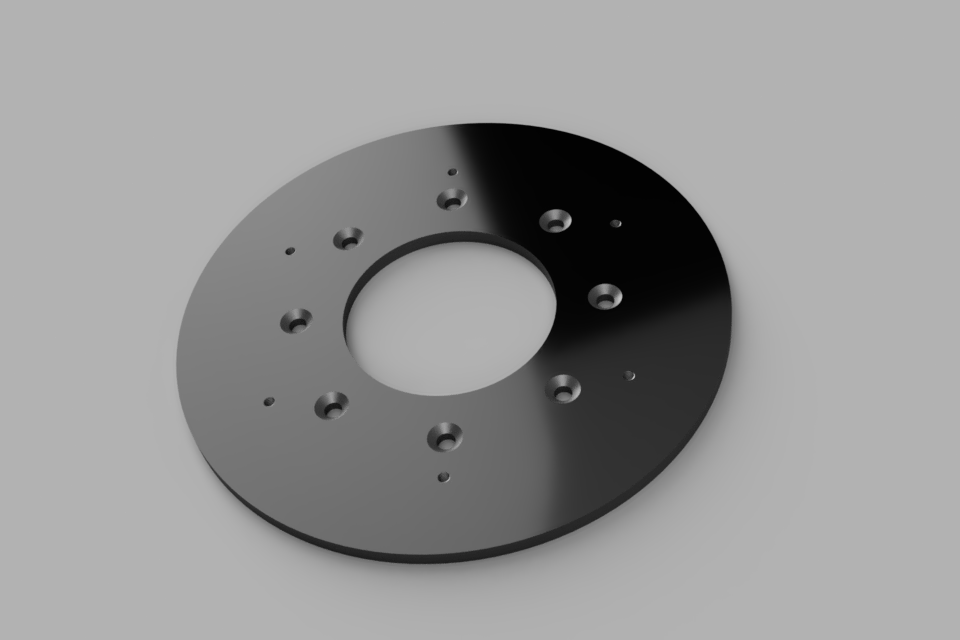

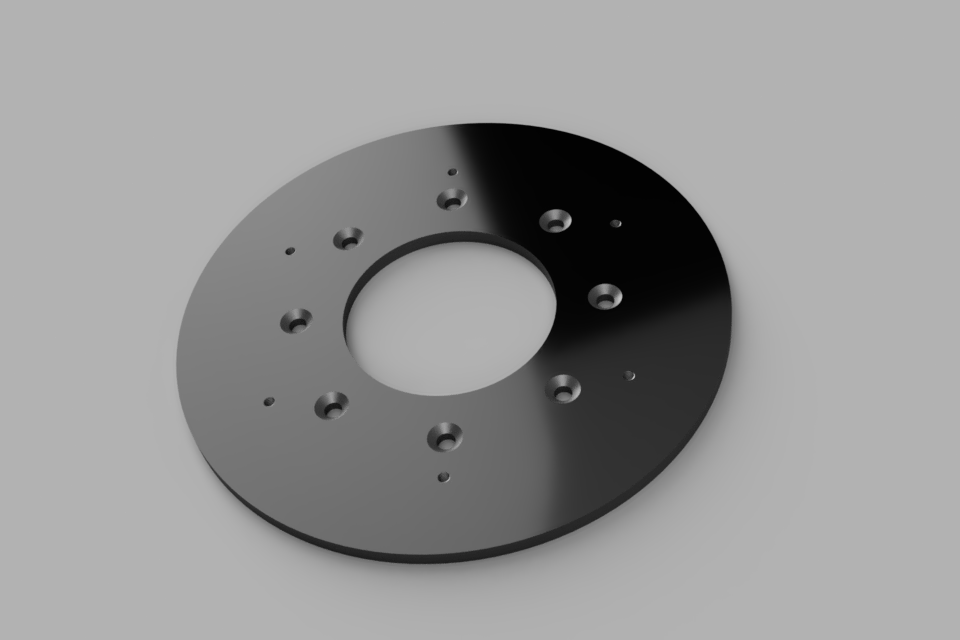

Custom Pier Plate Adapters

Custom pier plate adapters engineered for your mount and pier. Laser-cut steel or aluminum with ±0.005" precision. No flexing under load. Design-to-delivery service.

Out of stock - will ship when available

Your Mount. Your Pier. A Perfect Fit.

Not every mount fits a standard pier top. Different manufacturers use different bolt patterns, flange sizes, and mounting interfaces-and when you need a precision adapter to mate your mount to your pier, off-the-shelf solutions often don't exist. That's where we come in.

Dark Dragons Astronomy designs and manufactures custom pier plate adapters for observatory installations. We handle the engineering and partner with precision fabricators to deliver plates that fit your exact specifications-whether you're building a new observatory from scratch or adapting a new mount to an existing pier.

Why Custom Matters

We've seen what happens when pier plates aren't engineered properly: flexing under load. A plate that deflects even slightly when your mount slews introduces vibration, throws off polar alignment, and turns what should be a solid foundation into a source of frustration. Your mount and imaging equipment deserve better.

Our pier plates are designed for the actual loads they'll carry-not just the static weight of your mount, but the dynamic forces during slewing and the moment loads from your optical train. We specify appropriate material thickness and geometry based on your setup, not guesswork.

Proven Partnership

Howling Coyote Remote Observatory:

We've been working with Howling Coyote Remote Observatory in New Mexico to design and manufacture custom pier plates for their professional imaging facility. Their installation features multiple telescopes on various mounts-Planewave L-Series, Astro-Physics 1100, 10Micron GM2000, and more-each requiring a precise pier interface.

These aren't theoretical designs. These plates are in service right now, supporting expensive equipment in a professional remote imaging operation. They work, they're precise, and they're built to last.

After proving the concept at Howling Coyote, we're offering the same design and manufacturing service to amateur astronomers, institutions, and anyone with a mount-to-pier compatibility challenge.

Key Benefits

Precision Where It Counts

We partner with OSH Cut-a US-based precision fabrication shop using 10kW fiber lasers and CNC equipment-to manufacture your plates. Standard tolerances are ±0.005" on cut features, which means your bolt patterns line up correctly the first time. No drilling out holes, no shimming, no hoping things fit.

Engineered for Your Load

Pier plates aren't one-size-fits-all. A plate designed for a 30-pound mount won't handle a 100-pound Pro system without flexing. We size material thickness and geometry based on your actual equipment-mount weight, optical train length, moment arms during slewing. The result is a plate that stays rigid under load.

Steel or Aluminum-Your Choice

Both materials work well for pier plates, with different advantages:

- Steel: Maximum rigidity, excellent for heavy mounts and permanent installations. Very stable across temperature swings. Available up to 1" thick.

- Aluminum: Lighter weight, naturally corrosion-resistant, excellent for portable setups or when weight matters. Can be anodized for a premium finish. Available up to 1" thick.

We'll recommend the right material based on your mount, pier, and usage-but the final choice is yours.

Features You Actually Need

Cable management cutouts? Height adjustment provisions? Access holes for pier interior wiring? We can incorporate these into your design. Tell us what you need, and we'll make it work.

What's Included

Design Services:

- Initial consultation to understand your requirements

- CAD design with proper bolt patterns, clearances, and load considerations

- Design revisions until you're satisfied

- Final drawings for your approval before manufacturing

Manufacturing:

- Precision laser cutting (±0.005" tolerance)

- Tapped holes where specified (6-32 through 1½-6 standard, M3 through M36 metric)

- Deburring and edge finishing

- Quality inspection before shipping

Delivery:

- Finished plate ready to install

- Hardware recommendations for your specific mount and pier

- Installation guidance

Technical Specifications

| Specification | Value |

|---|---|

| Materials | Steel (mild, A36) or Aluminum (5052, 6061) |

| Maximum thickness | 1.0" (steel, aluminum) |

| Cut tolerance | ±0.005" standard |

| Tapping range | 6-32 to 1½-6 (standard), M3×0.5 to M36-4.0 (metric) |

| Finishing options | Deburring (120-grit), graining (240-grit brushed) |

| Optional finishing | Powder coating, anodizing (aluminum) |

| Shipping | US only |

Mounts We've Designed For

German Equatorial:

- Astro-Physics: AP900, AP1100, AP1200, Mach1, Mach2

- 10Micron: GM1000, GM2000, GM3000, GM4000

- iOptron: CEM120, CEM70, GEM45, CEM40

- Paramount: ME, MX, MYT

- Sky-Watcher EQ6, EQ8, and similar

Alt-Az and Direct Drive:

- Planewave L-Series

- ZWO AM5 and AM3

- Custom alt-az configurations

Adapters Between Systems:

- Mount flange to different pier top diameter

- Bolt pattern conversions

- Legacy pier to modern mount interfaces

If your mount has a bolt pattern, we can design for it. Send us the specs or the manufacturer documentation-we'll figure out the rest.

Our Process

1. Initial Consultation

Contact us with your requirements:

- What mount do you have?

- What pier system? (custom, commercial, or DIY)

- Any special features needed? (cable management, adjustment provisions)

- Material preference?

We'll discuss feasibility and provide a quote.

2. Information Gathering

We need specifications:

- Mount manufacturer and model

- Mount bolt pattern and dimensions (or we'll look them up)

- Pier top diameter and bolt pattern

- Photos of your installation (helpful but not required)

3. CAD Design

We design your plate with:

- Precise bolt pattern matching

- Proper clearances and fitment

- Structural analysis for your load

- Any requested features (cable cutouts, etc.)

4. Design Review

You review CAD drawings before we manufacture:

- Verify dimensions and features

- Request modifications if needed

- Approve the final design

5. Manufacturing

Once approved, we send your design to OSH Cut:

- Precision laser cutting

- Hole drilling and tapping

- Deburring and finishing

- Quality inspection

6. Delivery

Your plate ships ready to install, typically within 3-6 weeks from design approval.

Installation Reality Check

Installing a pier plate is straightforward-you're bolting two things together.

Time required: 30 minutes to an hour, depending on access

Tools needed: Wrenches or sockets for your bolt sizes, torque wrench recommended

Skill level: Basic mechanical aptitude-if you can bolt on a wheel, you can install a pier plate

Pro tip: Check that your pier top is level before mounting the plate. A machinist's level or bubble level works fine. Shimming the plate to correct for an out-of-level pier is possible but annoying-better to get it right at the pier.

What You Need to Provide

- Mount specifications - Model number, bolt pattern, flange dimensions (or let us look them up)

- Pier specifications - Top diameter, bolt pattern, material

- Mounting hardware - Bolts to attach mount to plate and plate to pier (we'll recommend sizes)

- Photos - Current setup if you have one (helpful for understanding your situation)

What's NOT Included

Mounting Hardware: Bolts are specific to your mount and pier-we'll recommend what you need, but you'll source them locally or from the mount/pier manufacturer.

Powder Coating / Anodizing: Available but quoted separately. Basic deburring is included; premium finishes are optional.

Installation: You install the plate at your location. We provide guidance and support.

Typical Lead Times

| Phase | Duration |

|---|---|

| Design | 1-2 weeks (depending on complexity and revision cycles) |

| Manufacturing | 2-4 weeks (depending on OSH Cut queue and complexity) |

| Total | 3-6 weeks from approval to delivery |

Need it faster? Contact us-rush service may be available depending on OSH Cut capacity.

Pricing

Custom pier plates are quoted based on:

- Complexity of design

- Material choice (steel vs. aluminum)

- Size and thickness required

- Special features requested

- Quantity (multiple plates reduce per-unit cost)

To get a quote: Contact us with your mount model, pier information, and requirements. We'll provide a detailed quote covering design and manufacturing.

Common Applications

New Observatory Construction: Design your pier plate as part of the build-ensure a perfect mount interface from day one.

Mount Upgrades: New mount on an existing pier? Different bolt pattern? A custom adapter plate solves the compatibility problem.

Custom Pier Systems: Building a DIY pier from scratch? We'll design the top plate to match your mount exactly.

Legacy Equipment: Adapting vintage mounts to modern piers (or vice versa) often requires custom work. We've done it.

Why Dark Dragons?

We're astronomers. We understand the precision requirements because we use this equipment ourselves.

Proven track record. Our plates are supporting expensive equipment in professional installations right now.

Engineering focus. We don't just cut metal to a pattern-we design for your actual loads and use case.

Full service. Design through delivery, we handle everything. Questions during installation? We're here.

Get Started

Ready for a custom pier plate?

Step 1: Contact us with your mount and pier details

Step 2: We'll discuss your project and provide a quote

Step 3: Approve the design and we manufacture

Step 4: Receive your plate and mount with confidence

Contact: Email us or reach out on Discord at https://discord.gg/fMV6f5PY

Need help? Join our Discord community for installation guides, troubleshooting, and direct support.